Copyright:FUJIAN XINGHANG MECHANICAL CASTING CO.,LTD. Copyright © 2018 All Rights Reserved. 闽ICP12013241号-1

Powered by www.300.cn

Contact Us Fujian Xinghang Machinery Casting Co., Ltd.

Address: Sanzhan, Wenwusha Town, Changle District, Fuzhou, Fujian Province

Telephone: 086-0591-28789677

ABOUT US

Our History

In 1993, Fujian Xinghang established Fuzhou Jianhong Casting Factory, the predecessor of Fujian Xinghang Machinery Foundry Co., Ltd. in Fuzhou. The company was relocated to Changle District, Fuzhou in 2003 and changed its name to Fujian Xinghang Machinery Foundry Co., Ltd. The company’s business covers casting and machining.

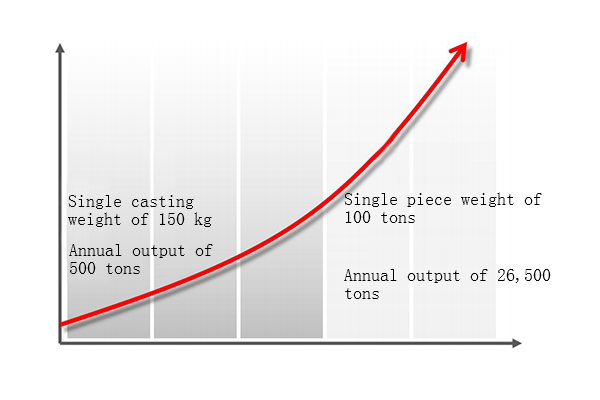

Under the leadership of Chairman Chen Yigui, the company strictly follows the standards of the foundry industry and strictly carries out production and business activities. After more than 20 years of hard work, the company has made rapid expansion in production scale and business volume, growing from the original output of 150 kg of castings into the production scale of 106 tons of single castings, putting an end to the history that large-scale castings of more than 50 tons in Fujian could only be sent to other provinces for production; the annual output grew from the initial 500 tons to nearly 30,000 tons; the business scope was initially confined to the surrounding areas. The products have been sold to Tianjin, Shanghai, Tibet, and other places, and also exported to Germany, South Korea, India, Taiwan and other countries and regions. The company has grown from a small workshop to a large modern private enterprise with an annual output of 40,000 tons of castings and a processing capacity of 10,000 tons, specializing in foundry production and machining. It has become the vanguard of China's foundry sub-industry and the leading enterprise in the foundry industry in Fujian Province. Its production capacity ranks first in the province. The products cover the high-end mold industry, bridge components, metallurgical equipment, engineering machinery, wind power and hydroelectric equipment, marine engineering equipment and other national key projects, and national key equipment. In January 2010, the company became the "casting base for Shanghai Baosteel Machinery Manufacturing Division." In 2016, it was awarded “Famous Trademark of Fuzhou” and in 2017, it passed the certification of China Classification Society.

As the company continues to grow, the focus has been laid on how to be stronger and better. The company actively explores the road to the industrialization of large steel castings, and regards raising the level of casting technology in Fujian Province as a matter of urgency and duty. To this end, Mr. Chen Yigui, chairman of the company, looks out into the future, focusing on the concept of high-end, innovation and green, to promote the transformation and upgrading of traditional casting industries in the green direction, and achieve the maximization of technology, personnel, and funds. The company is advancing toward the goal of becoming bigger and stronger. Driven by innovation, it strives to boost technological advancement in the industry, actively explores the application of patented technologies and other high technologies in the production process, and continuously increases the proportion of new technology products in sales. The company was certified as “National-level High-Tech Enterprise” in 2014 and passed the review for high-tech companies in 2017. In 2016, it was named "Science and Technology Giant Leading Company” by the Department of Science and Technology of the Province.

The company has established “Fujian Large Steel Casting Enterprise Engineering Technology Research Center” approved by the Provincial Department of Science and Technology, as well as the “Fuzhou Municipal Enterprise Technology Center” and “Expert Workstation” approved by the Fuzhou Municipal Government. Relying on these centers, the company has established cooperative relationships with universities and research institutes to carry out industry-university-research cooperation. We have also established a technology R&D cooperation and innovation new system for the research and development of large-scale steel castings and industrialization pilot projects to fully utilize the advantages of universities and enterprises and develop large-scale steel casting manufacturing technologies. The company is dedicated to strengthen school-enterprise technical exchanges, to grasp the key and core technologies in the large-scale steel castings manufacturing industry, gradually promote the adjustment of the industrialization structure, and finally explore a road to the industrialization of large-scale high-quality steel castings for green production.

The company is carrying out the “R&D and industrialization of the high-end wear-resistant and heat-resistant steel castings” STS Fujian project in cooperation with the Institute of Metals of the Chinese Academy of Sciences, the “development of CAD/CAE technology service platform for large-scale steel castings” in cooperation with Fuzhou University, and the “Research and Application of Liquid Steel Purification Technology in LF Refining of Extra-large Steel Castings” project in cooperation with the Fujian Institute of Technology, to improve the process and technical level of casting in Fujian Province; the company is also carrying out the “Research on Localization of Casting Production of Key Equipment in the Metallurgical Industry” in cooperation with Baosteel Co., Ltd., and the special research on "improvement and upgrade of cold casting material quality and improvement of cold-type safety and service life" in cooperation with Wuhan Iron and Steel Roller Co., Ltd. At the same time, the company pays close attention to the implementation of the transformation of scientific and technological achievements, having achieved good results. The company has 45 independent intellectual property patents, including 3 invention patents. The company was awarded “Model Intellectual Property Enterprise” by Fuzhou Municipal Government in 2015. The development of these projects has laid a good foundation for improving product quality and enhancing the overall quality of the enterprise, and for Fujian Province to catch up with the advanced casting levels at home and abroad.

The company strengthens the integration of industrialization and informationization, and actively promotes the organic integration of traditional industries with information and intelligence. In the R&D and design of products, the company adopts the computer simulation technology and gives play to the Internet+. The visual casting process is promoted, and the information technology of “Smart Workshop Execution System” is adopted to realize the fine control of the process. In 2015, the company was selected by the Ministry of Industry and Information Technology as a pilot enterprise for integrated management of the industrialization and informationization” and passed the evaluation. The company has also accelerated the pace of transformation and upgrading from "ordinary manufacturing" to "smart manufacturing." In 2017, it was awarded "Fujian Smart Manufacturing Pilot Demonstration Enterprise" by the Economic and Information Technology Commission of Fujian.